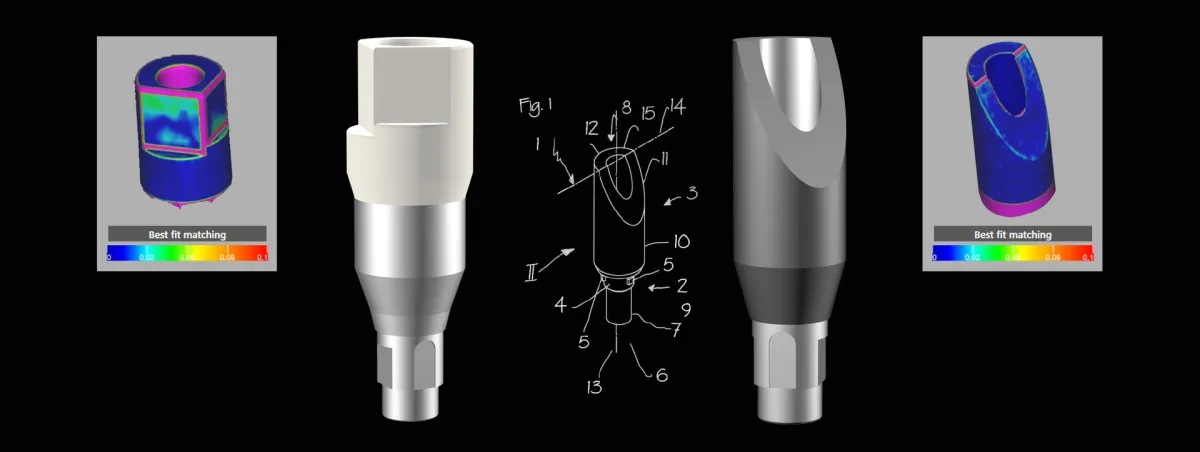

As we all know the basis of a perfect dentures supply is a perfect scan result – the tool which we use for that is the scanbody, that is the reason why we approached the design of the scanbody again. Even our old version of the Scanbody has a very good matching accuracy. But as you can see, we have a slightly inaccuracy in the angle. For Dental Direkt - good is not good enough, we always want to provide the perfect quality, as we are known for from the zirconia.

.

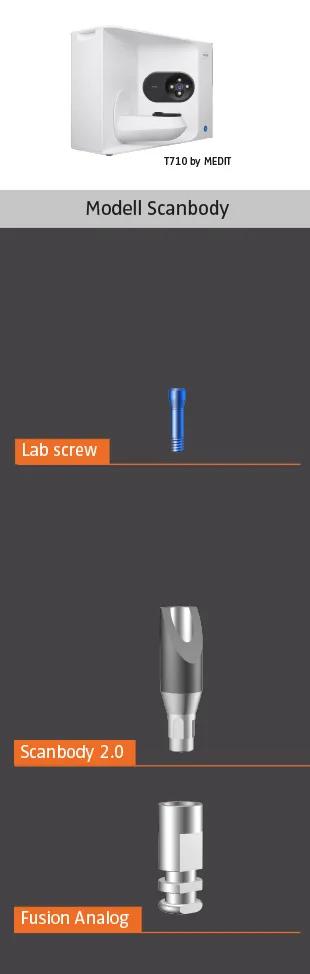

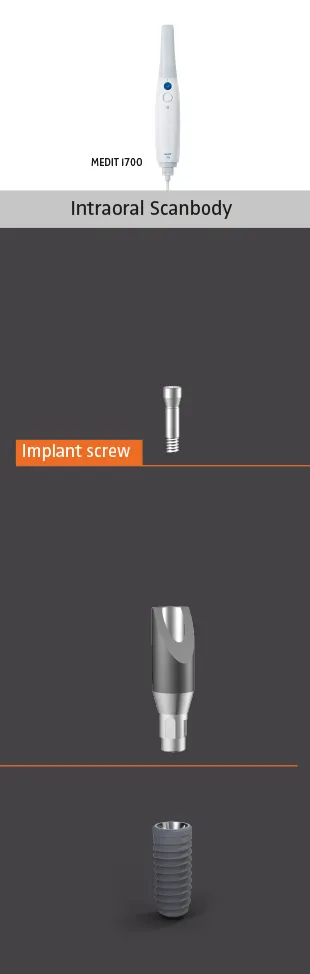

We changed the material from a combination of peek and titan to a solid titan construction. The reason of this is, that we wanted to get rid of the connection of 2 materials which causes a small risk of a deformation of the peek part. Also, the connection of the materials causes a risk of concentricity which will not be noticed in the matching. Later, the difference in centric will cause a problem with the implant connections.

With the change of the material we also were in the situation to optimize the surface of the titanium because untreated titanium has no good scanning characteristics. We tried out a lot of different coatings and found out a coating with optimal scan characteristics and a high accuracy of the coating itself.

Our goal was a very slim form with enough scannable surfaces to reach the perfect positioning precision. In process we learned a lot about the importance of the size of the top surface of the scanbody to guarantee a perfect height accuracy of your work. Therefore, we constructed an inclined surface which will help the user in case of difficult implant situations.

We are happy to advise you:

Jakob Röttger

Business Development Manager

Telefon +49 5225 86319-252

Leon Prüßner

Vertrieb National

Telefon +49 5225 86319-36