Your partner for dental

Milling services

Our expertise includes in-depth knowledge of materials and the highest quality standards. A team of highly qualified machinists, dental technologists and users guarantees customized solutions. Innovation and a strict exchange of best practice ensure the highest safety standards for products and processes. Those who have can make the difference!

We create synergies from analog craftsmanship and digital workflows on over 2000 square meters. As a manufacturer, we use our own material warehouse and state-of-the-art machines for processing and production.

By bundling expertise under one roof, short internal paths and our principle of "cross-know-how", we ensure smoothly coordinated processes. The result: high-quality milling service products at a fair price, as an in-house production or outsourcing solution - your profit, your decision.

Transparent production

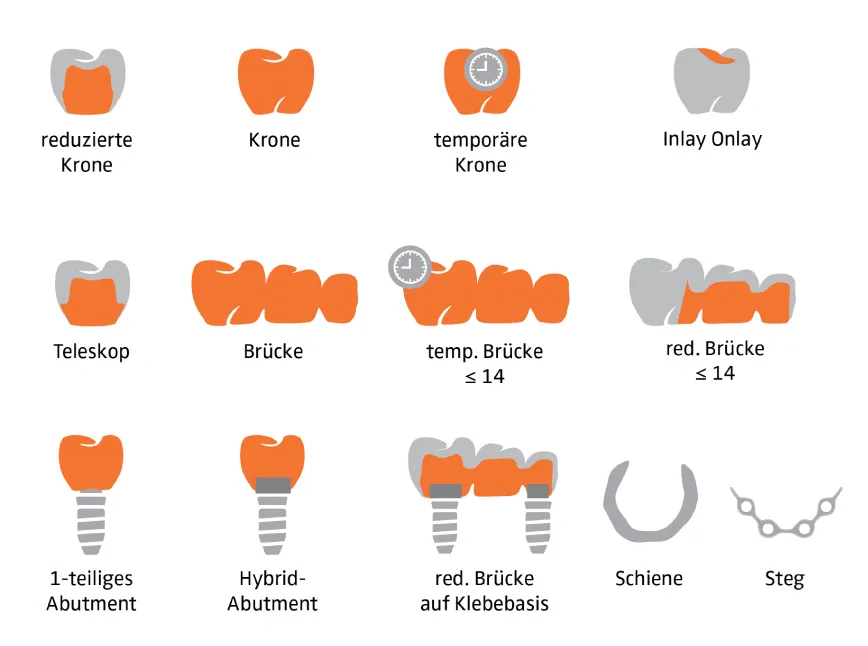

Inlays, onlays, crowns, bridges and dentures are made of zirconia or polymers and offer a perfect fit:

Further advantages:

Esthetics without compromise over 430 zirconia variants for all technical indications! Two esthetic lines for all esthetic requirements! High-performance ceramics from Europe's largest manufacturer of dental zirconium oxide.

The quality guarantee: »Made in Germany«

Tested and 100% biocompatible. CAD/CAM high-performance polymers for splints, bite regulators, drilling templates, temporary crowns, temporary bridges, implant-supported restorations, fixed and removable frameworks and denture bases.

These play an important role in the manufacture of dental prostheses. In contrast to gold-based materials used in the past, non-precious metal alloys offer a more cost-effective alternative with very good properties.

These are usually alloys based on cobalt-chromium (CoCr) with additions of molybdenum, manganese, silicon and tungsten. Non-precious metal alloys are characterized by high biocompatibility, corrosion resistance and strength. They are therefore used in a wide range of applications:

Titanium is establishing itself as the material of choice in modern dentistry. Its outstanding properties make it ideal for use in implantology and prosthetics

Advanced manufacturing processes for patient-specific tooth replacement solutions - dental implantology and prosthetics are undergoing a transformation as 3D printing with resin materials finds its way into modern manufacturing processes. High-precision 3D printers enable the patient-specific creation of dental prosthesis solutions that meet the highest standards of precision, biocompatibility and functionality.

Our high-end milling and grinding machines guarantee absolute accuracy of fit, extreme speed and maximum efficiency. Innovative technologies and optimally coordinated processes - from hardware and software to materials and processing tools through to the CNC milling machine - ensure precise results at the highest level. In contrast to additive laser melting, in which material is built up layer by layer, milling is a subtractive process. Material is milled out of a block until the desired end product is created. This "technical sculpting" enables consistently high production quality, which is particularly important for dental technology products.

LaserMelting (selective laser melting) builds 3D objects from the finest metal powder, which are precisely melted by laser.

Compared to other processes, LaserMelting enables significantly more complex geometries and surpasses dental casting in terms of material quality and precision. Even 16-unit restorations can be realized without any problems.

Our process, specially adapted for dental technology, guarantees the highest accuracy of fit with the fastest delivery times. Different delivery variants give you the choice of processing depth.

At Dental Direkt, we rely on the innovative DLP-Technology (Digital Light Processing) and thus offer you 3D printing in dental technology at the highest level.

Your path to the perfect denture begins with your idea. Whether you send us a hand-made model or scan data (intraoral scan or model scan) is irrelevant. Our experienced CAD specialists will implement your vision precisely and reliably using the latest 3D technologies.

Precision is our benchmark: surface testing and measuring procedures at Dental Direkt. State-of-the-art testing and measuring procedures guarantee the highest quality and reliability of dental restorations.

Surface inspection:

Measuring procedure:

Continuous quality control for your satisfaction.

Diversity wins.

Dental Direkt – the complete provider in the dental sector